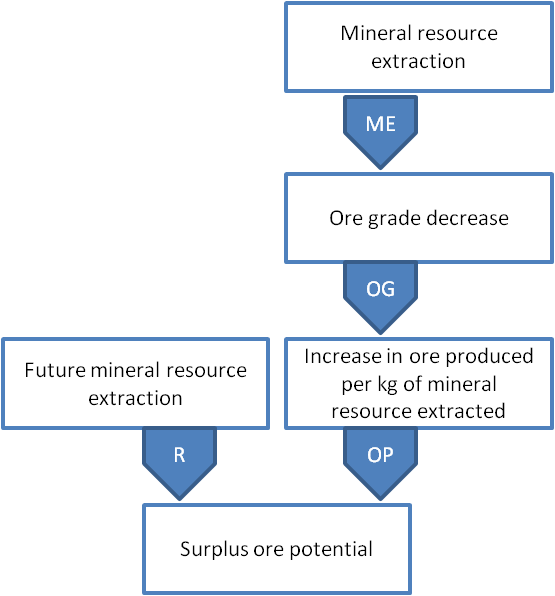

Modeling approach

An average approach is used to calculate the characterization factors. By calculating on basis of

cumulative grade-tonnage relationships the increase in ore amount for all future mineral extraction and

then dividing it by the future mineral extraction, average CFs are derived. These CFs are used to assess

the potential impacts of mineral resource extraction worldwide.

Value choices

- Time horizon: infinite

- Maximum amount of a mineral resource to be extracted: two different reserve estimates were applied

in the calculations, reserves and ultimate recoverable resource

- The choice of discounting: no discounting to future effects is applied

Spatial variability

Not applicable

Characterisation factors

The equation for calculating the characterisation factor (CF),

expressed as the Surplus Ore Potential (SOP), is defined as the extra amount of ore produced in the

future per unit of mineral extracted (kgore/kgx) is:

$$\mathsf{CF_{x}=\frac{\int_{CME_x}^{MME_x}\left(\Delta OP_x\right)\mathit{d}CME_x}{MME_x-CME_x}}$$

where OPx is the ore produced per amount of

mineral resource x extracted

(kgore/kgx), MMEx (kgore/kgx)

is the maximum amount to be extracted of that mineral, and CMEx is the cumulative amount of mineral x currently extracted.